Mill Finished And Anodized Surface Treatment Industial Aluminum Profile 6000 Series

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Mill Finished And Anodized Surface Treatment Industial Aluminium Profile 6000 Series

1) Al

Mill Finished And Anodized Surface Treatment Industial Aluminium Profile 6000 Series

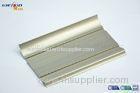

1) Aluminum alloy: AL6063/6061/6005 or as for per customers' require.

2) Surface: anodizing colors, powder coating, painting or mill finish.

3) Length: according to clients' requests

4) Packing: with plastic film and wrapped with kraft paper.or meet the clients' requires

6) Usage of the aluminum products: decoration, furniture, windows and door frame, curtain wall, construction, etc.

7) Certificate: ISO9001, ISO14001, OHSAS18001

Aluminium Profile / Extrusion

Aluminum extrusion is a technique used to transform aluminum alloy into objects with a definitive cross-sectional profile for a wide range of uses. The extrusion process makes the most of aluminium is unique combination of physical characteristics. Its malleability allows it to be easily machined and cast, and yet aluminum is one third the density and stiffness of steel so the resulting products offer strength and stability, particularly when alloyed with other metals.

Alloy Chemical Element

|

Alloy |

Si |

Mg |

Fe |

Cu |

Mn |

Zn |

Cr |

Ti |

|

6063 |

0.2-0.6 |

045-0.9 |

<0.35 |

<0.1 |

<0.1 |

<0.1 |

<0.1 |

<0.1 |

|

6061 |

0.4-0.8 |

0.8-1.2 |

<0.7 |

0.15-0.4 |

0.15 |

0.25 |

0.04-0.35 |

<0.05 |

Brief Introduction.

Quality is the essence of the the company and creates the future. It is the most important thing in MAXL. We put the quality as the emphasis since the very beginning of establishing the factory and it has penetrated into the market of aluminium profiles industry. For quality guarantee and cost control, MAXL has introduced advanced producing and testing equipment successively from Germany, Japan, and USA. MAXL has built an inspection center which has first-class level in domestic aluminium industry. We had emphasized on the introduction of Spectrometer from USA, Ultraviolet manual weathering instrument from America, Q-FOG spraying tester, High and low temperature electronic omnipotent tester from Japan, Microscope from Japan , and so on. Advanced testing equipment has provided a reassuring guarantee for the testing of performance of products. In one word quality is the soul of our company.

Packaging & delivery

1.Packaging details: EPE + Bubble film + Corner protection + paper + plywood + wood strip jointer

2.Delivery time for samples: about 5 days for sample production after all material confirmed.

3.Delivery time for mass production: 15 work days.

Our Advantages:

1. Precision machining and cutting: tolerance can be controlled within 0.2-0.5 mm in length, 0.05mm for holes.

2. All processes is controlled in the same factory to ensure to the good quality and lead time.

3. We are skilled in designing and developing special aluminum heat sink.

4. OEM and ODM service is available.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

MAXL INTERNATIONAL GROUP CO.,LTD [China (Mainland)]

Business Type:Manufacturer

City: Liaocheng

Province/State: Shandong

Country/Region: China (Mainland)